Aerial thermography

Aerial thermography by drone is mainly used for the thermal diagnosis of industrial sites and buildings or in the search for malfunction points on electrical transport and production installations.

Our partners

Drone thermography

420 thermal inspections since 2012

Our teams have thermographed solar panels, heritage, heat networks, heavy industries and many more. These different aerial inspection frameworks have enriched our expertise and provide you with qualified results. We provide you with a precise and synthetic report that accompanies you in your decision-making

- ^INTERVENTION IN EUROPE

- ^MORE THAN 300 CUSTOMERS

- ^DGAC / PREFECTURE / ARMY AUTHORISATION

years of experience

Teams trained and qualified in aerial thermal analysis by drone.

Our expertise

The different application areas of aerial thermography

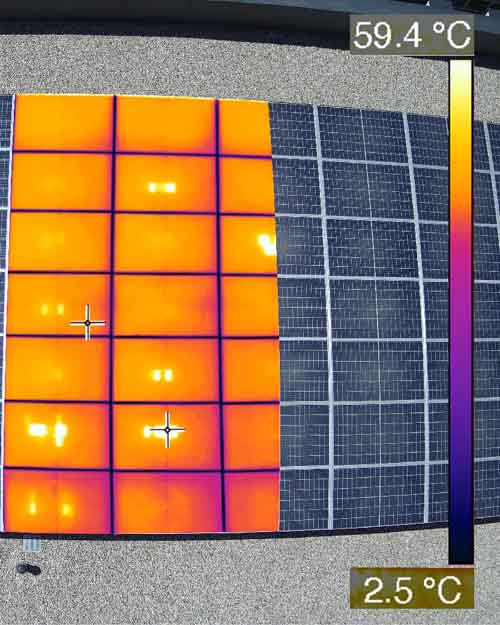

Photovoltaic park thermography

We inspect solar power plants from 50KWH to 100 MWH. From the simple roof to the park of several hectares through the agricultural roofs.

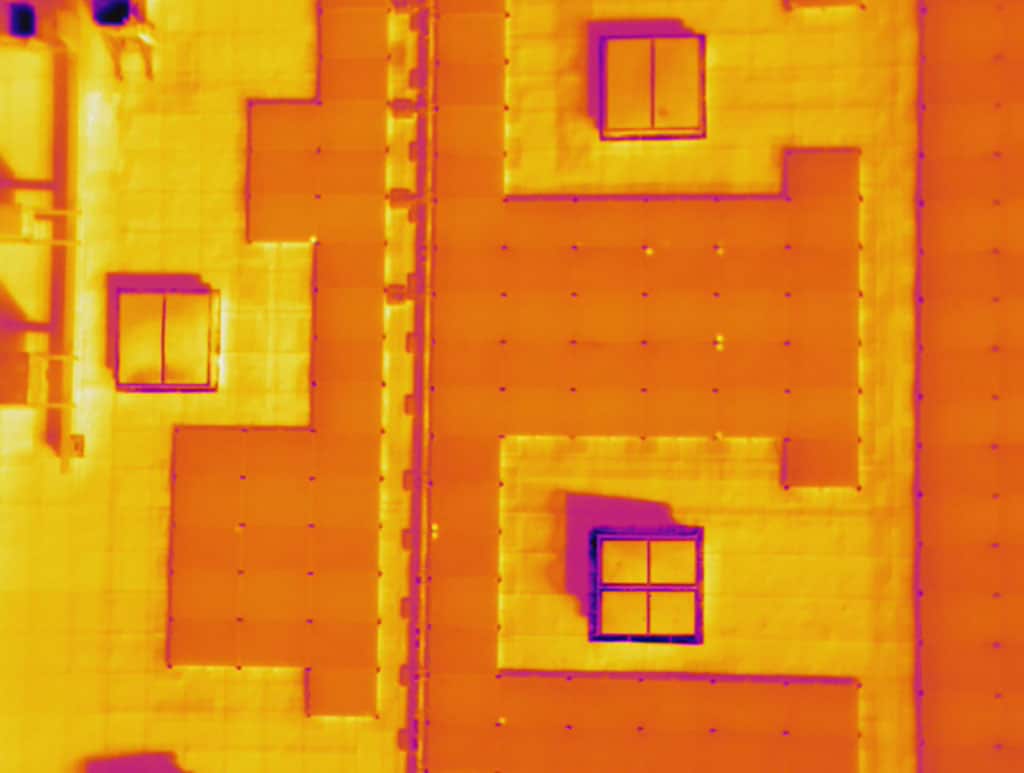

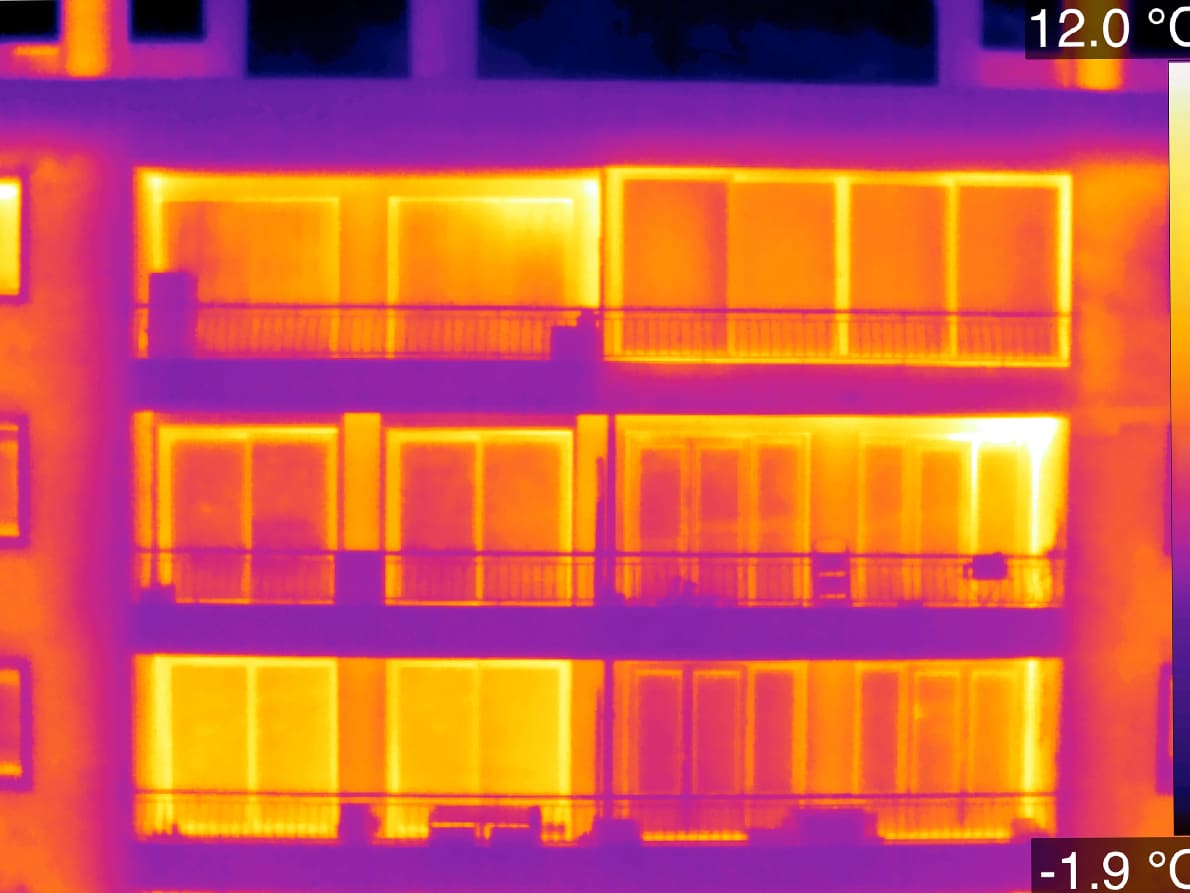

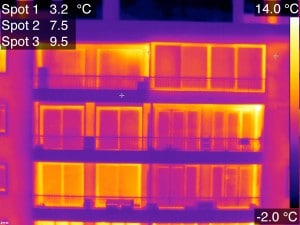

Building thermography

Identification of thermal anomalies specific to building pathologies. Collective, individual and industrial. Thermal bridges, degradation or lack of insulation.

Industrial thermography

Thermal inspection without production stoppage. No human commitment. Aerial thermography on sensitive sites: SEVESO, nuclear, army… Team trained in industrial risks.

METHODOLOGY

Thermal inspection process

Specifications

On-site capture

Creation of a secure area, flight plan, aerial thermography, customer video feedback.

Exploitation of renderings

Post-inspection meeting. Exchange on the use of renderings.

The prerequisites for each subject

Certain meteorological conditions must be respected to ensure a reliable thermal inspection : sunshine or cloud cover, humidity, wind, outside temperature and the temperature of the subject.

Questions about your subject to thermograph?

Our thermal inspections and reports also consider the following :

- 5The emissivity of the inspected material

- 5The nature of the surfaces

- 5The thermal sensitivity of the camera

- 5Thermal conductivity

- 5The inspection angle relative to the observed surface

The conditions of the thermal inspection

In the case of aerial thermal inspection, each subject requires its own capture methods and conditions.

A thermal inspection of solar panels

will require clear skies, clean panels, and maximum sunlight so that the plant produces at least 70% of its capacity.

Learn more about photovoltaic parks >>

Aerial building thermography

is carried out at night, so that the sun does not imprint the facades. The building must be heated to increase the difference between the outside and inside temperature.

Learn more about building thermography >>

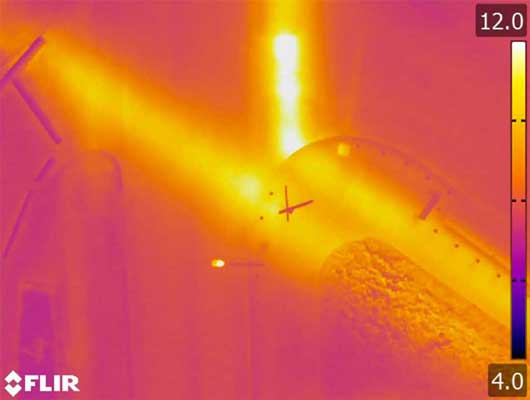

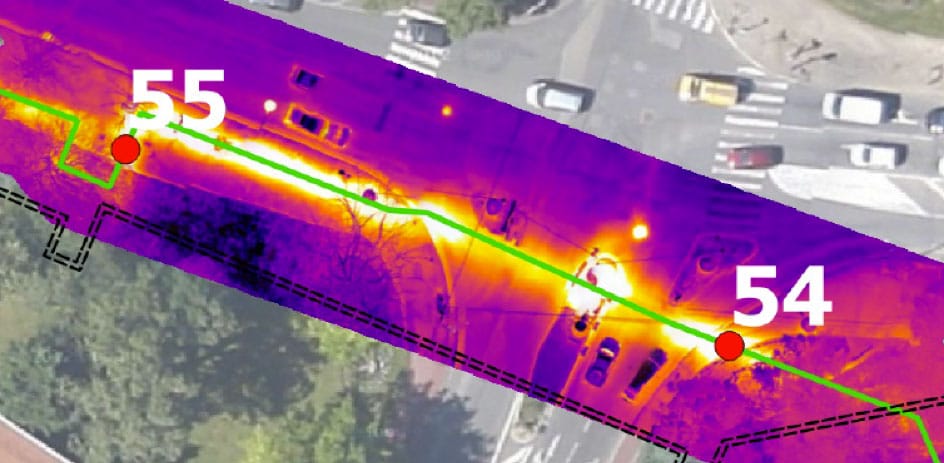

The thermal inspection of heat networks

is carried out during winter periods with maximum load on the network. The outside temperature should not exceed 10°.

Learn more about heat networks >>

- 5High-resolution FLIR thermal camera

- 5Rainproof IP43-certified drone

- 5Flight time over 30 minutes

- 5Double visible / thermal sensor

FAQ

Thermographic inspection

Frequently Asked Questions

What do your thermal reports look like?

What thermal camera do you use?

Working on major projects in the field of aerial thermography, such as the scanning of 250 homes for GrDF, or the inspection of 75,000 photovoltaic panels for Akuo Energy, has enabled us to improve our acquisition processes and our know-how.

To guarantee optimal quality and a high-resolution image, we are equipped with the Flir XT2 thermal camera, which has the most efficient onboard thermal sensor on the market (640 x 512 pixels) and offers a thermal sensitivity of 0.04 °C.

We have an RGB sensor coupled with the thermal sensor, which allows to compare the thermal image with a real photo and thus have more details of the subject to be inspected.

How is aerial thermography performed?

We plan our flight plan and adapt our aircraft to different projects depending on the subject to be thermographed, the location, the area to be covered and the time of year.

We use two capture modes depending on the applications. During the thermography operation, our onboard measuring devices record the thermal image as well as a digital photograph serving as a reference. The point of view chosen for the thermal measurement is immediately identifiable and allows to accurately validate the covered space and the defective zones (thermal bridges, missing insulation, energy-consuming zones).

We plan our flight plan and adapt our aircraft to different projects depending on the subject to be thermographed, the location, the area to be covered and the time of year.

We use two capture modes depending on the applications. During the thermography operation, our onboard measuring devices record the thermal image as well as a digital photograph serving as a reference. The point of view chosen for the thermal measurement is immediately identifiable and allows to accurately validate the covered space and the defective zones (thermal bridges, missing insulation, energy-consuming zones).

The choice of a thermographic video capture is suitable for the inspection and detection of heat leaks on large surfaces. Once the leak has been detected, the photo takes over to record a geolocated thermogram of the area of interest, allowing precise analysis.

The choice of a thermographic video capture is suitable for the inspection and detection of heat leaks on large surfaces. Once the leak has been detected, the photo takes over to record a geolocated thermogram of the area of interest, allowing precise analysis.Who takes care of the thermal data acquisition?

We couple our thermal camera to a video feedback, ensuring a pre-rendering to guarantee the quality of the capture. The drone inspection of a building is done in a few minutes and our operator can thus carry out several dwellings or buildings per flight.

Our drone thermography solution, developed in partnership with France Infra Rouge, is one of the few to have been approved by the DGAC (General Directorate of Civil Aviation). Our advance in this area has pushed us to develop ever more efficient and reliable solutions, and our partnerships are moving in this direction.

We couple our thermal camera to a video feedback, ensuring a pre-rendering to guarantee the quality of the capture. The drone inspection of a building is done in a few minutes and our operator can thus carry out several dwellings or buildings per flight.

Our drone thermography solution, developed in partnership with France Infra Rouge, is one of the few to have been approved by the DGAC (General Directorate of Civil Aviation). Our advance in this area has pushed us to develop ever more efficient and reliable solutions, and our partnerships are moving in this direction.How are data analysis and recovery carried out?

Drone thermography shooting follows very specific rules. It is essential to respect them to maximise the recorded information and minimise artefacts, thermal reflections and other alterations that could compromise a rigorous analysis.

Once the thermograms have been calibrated (emissivity, atmospheric temperature, temperature range, etc.), we suggest writing a report offering different degrees of analysis: from simple interpretation of the thermograms to writing a heat balance of your installation by our expert partner in thermography. Finally, we are able to offer you a series of recommendations to reduce your energy bill.

>> An example of a mission: Thermal building inspection in Marseille

What is the inspection of photovoltaic parks?

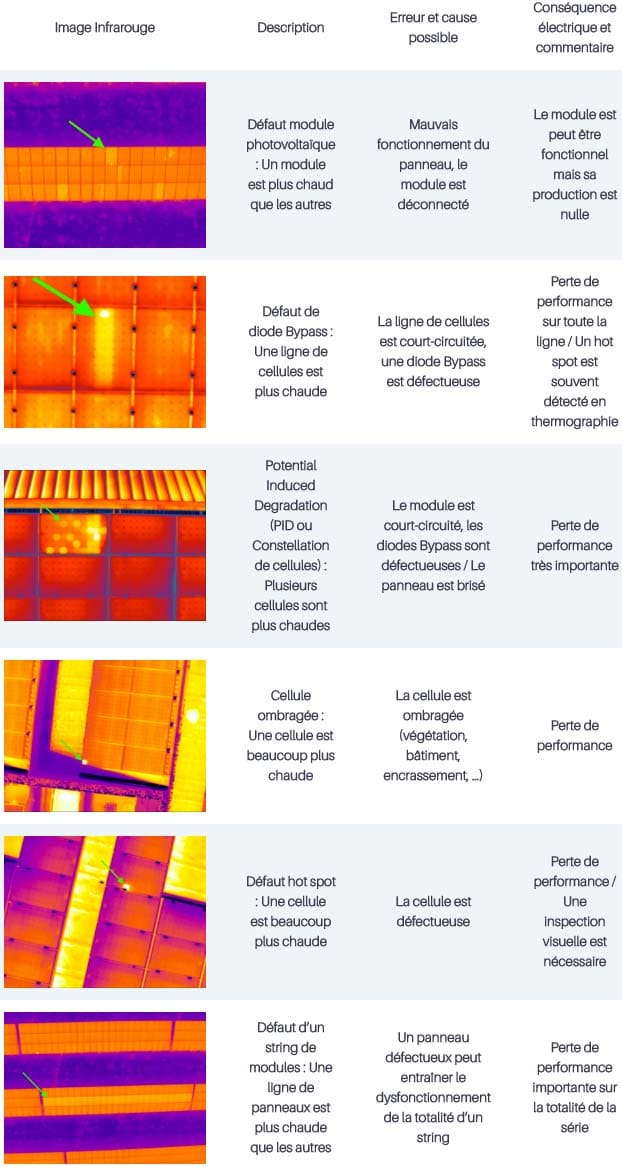

In parallel with these services, we have developed a methodology for inspecting photovoltaic power plants on the ground and on roofs. Our onboard thermal measurement solution allows us to quickly identify bypass cells, damaged connections, defective panels or rows of panels thanks to their particular thermal signature.

Our solution is innovative, reliable and very competitive. It is now used regularly by manufacturers in the sector.

Our solution is innovative, reliable and very competitive. It is now used regularly by manufacturers in the sector.

We also offer an initial diagnosis of the sources of malfunctions: identification of shadng, bypass cells or faulty connection boxes.

Our aerial thermography inspections by drone carried out on photovoltaic power plants allow to detect the majority of malfunctions.

We also offer an initial diagnosis of the sources of malfunctions: identification of shadng, bypass cells or faulty connection boxes.

Our aerial thermography inspections by drone carried out on photovoltaic power plants allow to detect the majority of malfunctions.

Demo film of our aerial drone inspection solutions:

Our aerial thermography inspections by drone carried out on photovoltaic power plants allow to detect the majority of malfunctions. Below is a table summarising the different types of faults most frequently observed :

What is heat network thermography ?

- Thermal sensitivity less than 34 mk

- Temperature range from -40 °C to +650 °C

- Embedded GPS allowing the georeferencing of infrared images

- Simultaneous thermal / RGB shots.

The drone and high-resolution camera combination allows to quickly cover your heat network installations with quality and at controlled costs.

The drone and high-resolution camera combination allows to quickly cover your heat network installations with quality and at controlled costs.

At the end of the drone inspection, we deliver to you the statement of the anomalies observed in thermography, a report on the progress of the mission and a map of your installation precise to a few centimetres in a few days.

At the end of the drone inspection, we deliver to you the statement of the anomalies observed in thermography, a report on the progress of the mission and a map of your installation precise to a few centimetres in a few days.

>> Learn more about the inspection of heat networks.

>> Learn more about the inspection of heat networks.

France Télévision Interview

Our drone thermography solution, developed in partnership with France Infra Rouge, is one of the few to have been approved by the DGAC (General Directorate of Civil Aviation). Our advance in this area has pushed us to develop ever more efficient and reliable solutions, and our partnerships are moving in this direction.

- 8, rue de la Madeleine - 69007 LYON

- 04 37 28 67 25

- contact@studiofly.fr

Discover our entity dedicated to audiovisual production