Industrial drone

INDUSTRIAL THERMOGRAPHY

Inspection of industrial equipment. Search for structural dysfunctions.

Industrial thermography

Inspection, maintenance, fault management

Industrial thermography by drone allows to inspect various industrial equipment in search of malfunction points without stopping production.

It facilitates the management of maintenance operations and allows to predict and avoid costly breakdowns. It is also a tool suitable for monitoring certain processes for a better control of the quality and consistency of production.

Industrial thermography methodology

What is industrial thermography by drone?

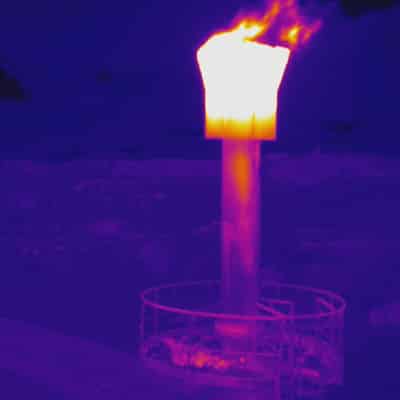

Industrial thermography by drone consists of inspecting complex industrial installations using a drone equipped with a high-definition thermal camera.

- 5A thermal mapping

- 5The thermogram

- 5A thermal 3D model

The advantage of this method is its simplicity of implementation. It avoids the use of scaffolding to provide access to the various machines or pipes. It guarantees the safety of operators and does not require a production stoppage.

Drone shooting, a simple and secure method

We provide easy-to-use rendering through our dedicated web application. No specialised software is required to consult the maps or models developed following our intervention.

Application of industrial thermography

Some examples of thermal inspections in an industrial environment

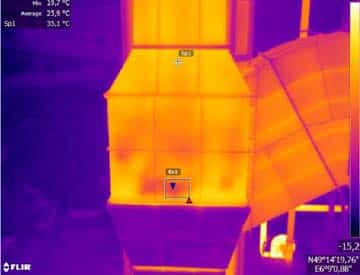

INSPECTION OF INDUSTRIAL FURNACES

Thermal inspection is a valuable tool for anticipating, planning and rationalising maintenance operations on this type of equipment.

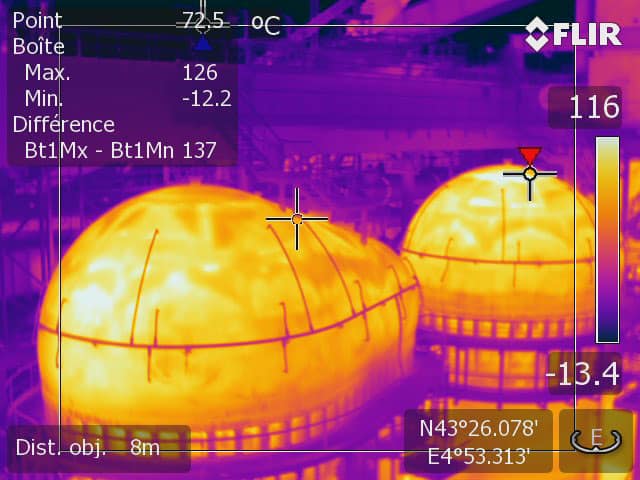

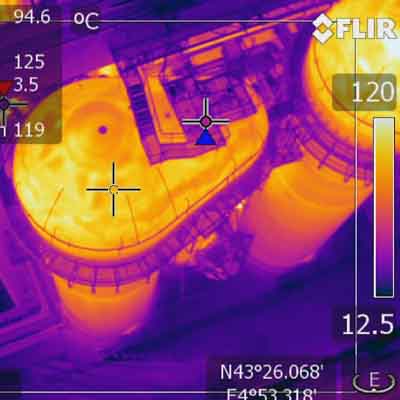

CONTROL OF LARGE-SCALE INDUSTRIAL INSTALLATIONS

The drone helps to easily visualise the highest or most difficult-to-access elements from various angles without taking risks.

For example, we can cite the thermal inspection of flares on petroleum sites.INDUSTRIAL PROCESS MONITORING

Industrial thermography by drone is perfectly suited thanks to its simplicity of implementation.

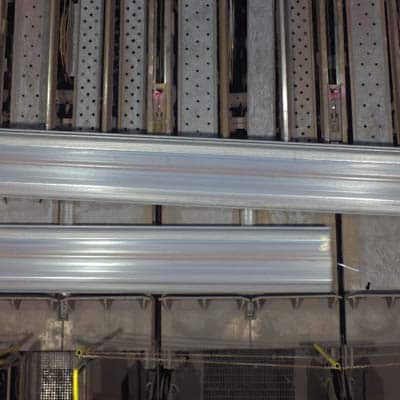

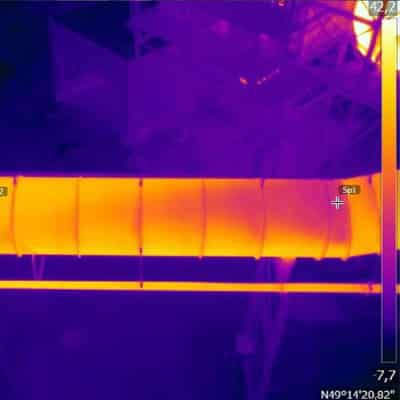

For example, we have monitored the cooling of metal sheet piles by drone in cooling towers to guarantee manufacturing quality.CONTROL OF HIGH-VOLTAGE LINES

It allows to easily detect localised overheating on cables or transformers due to the wear of certain elements.

In addition, the drone facilitates the visual inspection of the lines to monitor their condition and trigger maintenance operations.THERMAL INSPECTION OF PIPES

Industrial thermography by drone allows to check the internal condition of pipes carrying fluids, vapours or smoke.

The advantage is to be aware of any clogging to trigger a maintenance operation as quickly as possible before the obstruction. The temperature differences highlighted by the onboard thermal camera of the drone allow to visualise the presence of deposits in the pipes.Our expertise in aerial thermography also extends to other sectors of activity :

- 8, rue de la Madeleine - 69007 LYON

- 04 37 28 67 25

- contact@studiofly.fr

Discover our entity dedicated to audiovisual production